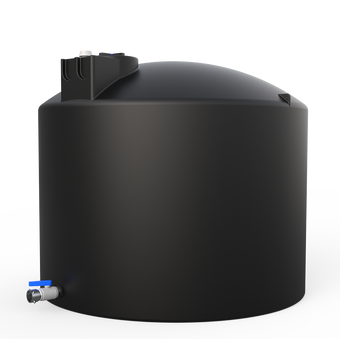

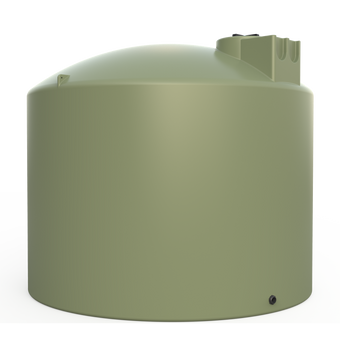

Bailey Tanks undertook a significant engineering project aimed at the development of its new product line: the Chunky Charlie underground water tanks. This project was characterized by a rigorous design and testing regime, beginning with an extensive Finite Element Analysis (FEA) phase. The purpose of this case study is to document and analyze the process and outcomes of the FEA testing carried out during the early stages of design, particularly focusing on top loading and hydrostatic uplift scenarios. This study outlines the methodology, background, materials selection, simulations, results, conclusions, and implications for tooling and final product design.

Chapter 2: Background of Finite Element Analysis (FEA)

FEA is a computational tool used to predict how a product reacts to real-world forces, vibration, heat, and other physical effects. In mechanical engineering, it allows for the simulation of stress, strain, and deflection in complex components. FEA reduces the need for multiple prototypes, saving time and cost, while providing deep insight into the product's performance. The technique subdivides a complex structure into smaller, simpler parts called elements, then solves equations that predict the behavior of each element under given loads.

Chapter 3: Objectives of the FEA Testing

The primary objectives of the FEA tests for Chunky Charlie were:

- Simulate top loading scenarios mimicking heavy earth coverage and surface traffic loads.

- Simulate hydrostatic uplift forces due to groundwater pressure.

- Evaluate material response and potential failure modes.

- Identify stress concentrations and refine structural geometry.

- Inform decisions before costly tooling began.

Chapter 4: Importance of Material Selection

Accurate simulation in FEA relies heavily on precise material data. For the Chunky Charlie underground tanks, selecting the correct polymer blend was vital. Material properties such as tensile strength, modulus of elasticity, Poisson’s ratio, and thermal characteristics needed to be captured correctly. Inaccuracies in these values can result in significantly flawed results.

Through the FEA process, we experimented with various materials, beginning with linear low-density polyethylene (LLDPE), which is the industry norm for rotational moulding due to its ease of processing and flexibility. However, as the design requirements for structural rigidity became more demanding, we transitioned to a high-density polyethylene (HDPE).

HDPE provided a significantly higher flexural modulus and greater stiffness, which directly reduced deflection under load-critical for underground applications where soil and water pressures are substantial. The material we selected is a newer generation of octene-based polyethylene, manufactured by Nova Chemicals in Canada. This material offered enhanced mechanical performance while maintaining good processing characteristics.

Octene is an eight-carbon alpha-olefin comonomer used in the polymerization of polyethylene. When used in producing polyethylene, it introduces longer side chains in the polymer structure, which helps increase toughness and flexibility without compromising stiffness. This balance was crucial for the tank’s structural performance.

The flexural modulus is a measure of a material’s stiffness or resistance to bending under load. A higher flexural modulus means the material will deform less when subjected to the same stress, which was particularly beneficial for our application to minimize displacement from top loading and hydrostatic uplift forces. By utilizing this high-performance octene-based HDPE, we ensured the Chunky Charlie tanks could maintain their shape, structural integrity, and functionality in demanding buried environments.

Chapter 5: Simulation Inputs and Parameters

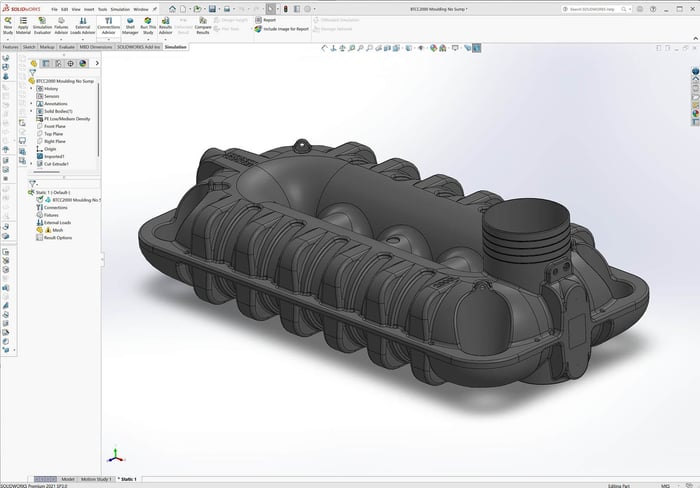

Our engineering partners in Melbourne carefully modelled the tank geometry using 3D CAD software, converting it into a meshed model suitable for analysis. Key parameters included:

- Boundary conditions (fixed restraints, supports)

- Loading scenarios (top load pressures, buoyancy forces)

- Environmental conditions (soil load, water pressure)

- Contact interactions (soil-tank interface, internal baffles)

Chapter 6: The Engineering and Testing Environment

All FEA modelling and simulation work was performed in Melbourne by an external team of experienced engineers contracted by Bailey Tanks. These professionals brought significant expertise in structural plastic analysis. They employed industry-standard FEA software such as ANSYS and SolidWorks Simulation.

Chapter 7: Results and Observations

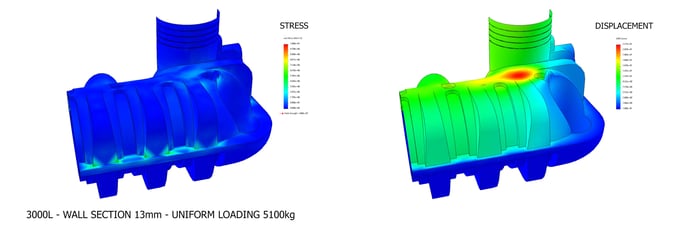

The FEA simulations produced highly encouraging results:

- The tank design demonstrated strong resistance to top loading with minimal deflection.

- Hydrostatic uplift scenarios revealed predictable deformation patterns, all within safety tolerances.

- Stress concentrations were found and resolved through minor geometric changes.

Chapter 8: Iterations and Final Changes

Thanks to the insights gained during this phase, the design underwent final tweaks. Rib spacing and wall thickness were adjusted, corner fillets were optimized, and internal stiffening was improved. These changes enhanced load-bearing capability and reduced material usage.

Chapter 9: Preparation for Tooling

The success of FEA allowed us to proceed confidently toward tooling with a highly optimized design. By resolving key structural issues early, we avoided the risk of costly revisions during production.

Chapter 10: Future Testing and Conclusion

With prototypes scheduled, we plan to conduct real-world physical testing as a second validation phase. However, FEA gave us the opportunity to catch and correct design flaws early, reinforcing the value of simulation in modern engineering.

The Chunky Charlie Underground Tank project exemplifies how rigorous engineering, thoughtful material selection, and advanced simulation tools can produce durable, efficient, and innovative underground tank solutions.