Have you ever wondered what happens to the plastic bottles you put in the recycling bin? Did you know Bailey uses post-consumer recycled materials our production process. In this video Peter Wolfkamp talks us through a recycling journey that may start and end in your home.

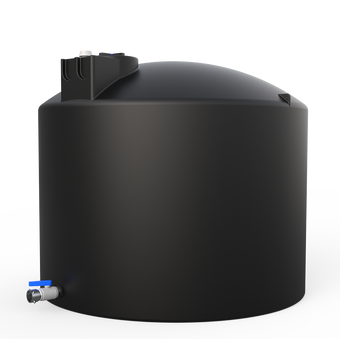

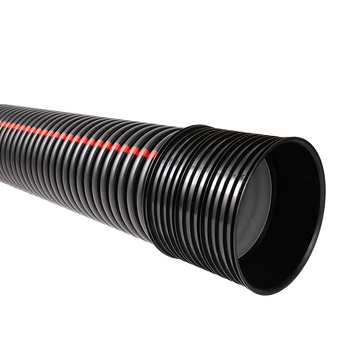

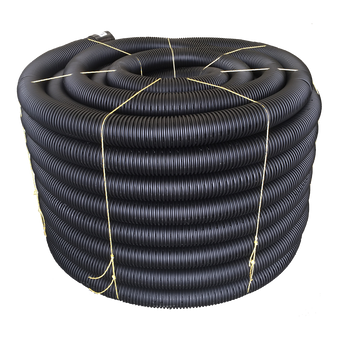

At the Baileys factory, the cleaned and processed plastic pallets are used in the manufacture of non-potable products, such as our Black Snake or Bazooka Culvert, which could be part of your drainage solution.

Bailey Tanks has a strong commitment to sustainability and innovation. each week, we use approximately 10 Tonnes of recycled HDPE plastic, which is the equivalent of 200,000 milk bottles.

We are proud to align with the principles of a circular economy, with sustainability and innovation at the core of our company. Our innovative journey from waste to resource not only contributes to environmental conservation but also highlights the potential for creative solutions in building a more sustainable future.

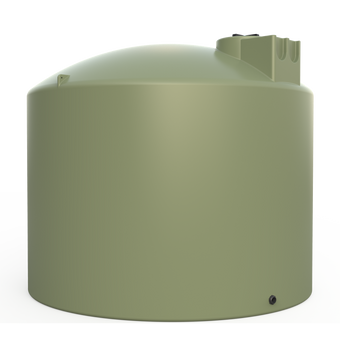

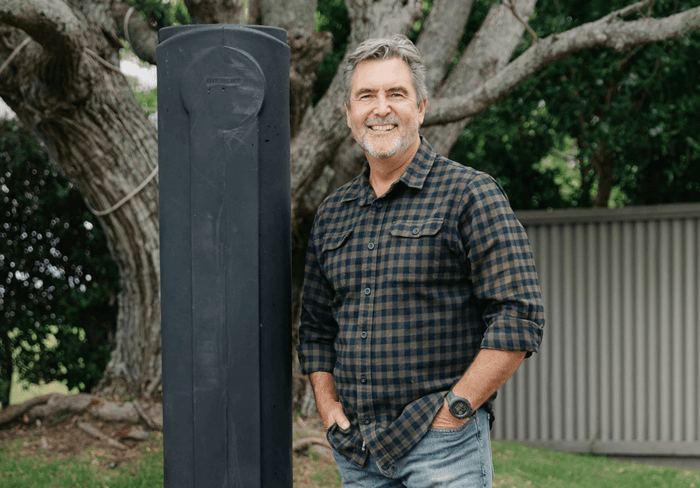

We also offer a tank recycling program for repurposing end-of-life tanks. The process begins when customers return their old tanks, we accept any PE tanks, not just our own. These pieces are then collected and sent to a third-party partner, where the material is cleaned and processed into usable material. It is then returned to us to be moulded into a brand-new water tank.

We use this recycled material to produce a slimline tank non-potable 2000L and 3000L tanks nicknamed "Recycled Ruth". These are slimline water tanks perfect for the urban setting. These tanks are designed for non-potable sources, such as rainwater harvesting and reuse, as they are made with 100% recycled materials.